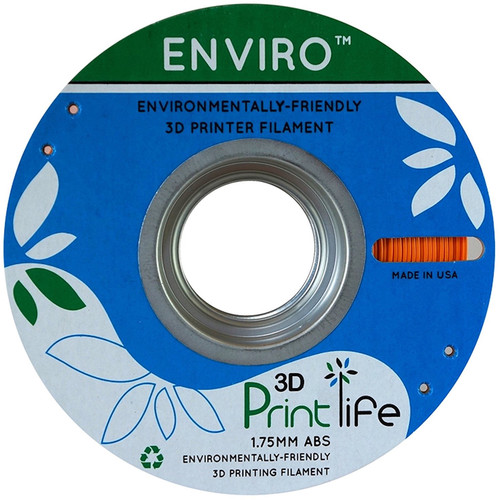

Perhaps the use of environmentally friendly filament will never have a huge impact on global CO 2 emissions, but desktop 3D printing is just at the beginning of its evolution and it is better to pick up good habit from the start. Sure, it is still mostly a matter of long tail, for now, but it is already paying off. Feel great about your world,” apparently struck a chord with many users and, perhaps even more importantly, with retailers that will be strategic in 3D printing adoption by the larger public. PLAyPHAb is also packaged in the same colorful 100% recycled cardboard spool allowing for zero carbon footprints.ģD Printlife’s claim, “Feel great about your prints. Although the exact blend may differ, this approach is not as entirely unique (colorFabb also uses PHA in some of its PLA): it is essential in strengthening the PLA while still allowing for the biodegradability of PLA. PLAyPHAb starts from PLA and enhances its polyester in order to provide the superior strength and durability of ABS. The company even donates a $1 from the sale of every spool sold to plant a tree. Packaged in a colorful spool made of 100% recycled cardboard with a tin flange that is also recyclable, ENVIRO is shipped with a wildflower seed insert that when planted grows perennial and annual wildflowers. 3D Printlife did not stop its eco-friendly forward thinking at just the filament either. This breakthrough filament has set the standard in “green” 3D printing when using ABS filament. The difference from other non-biodegradable ABS filament is that it is extruded with a bio-additive that allows the filament to break down to CO 2 and methane in an energy re-capture landfill setting. The LA company’s two main product lines are the ENVIRO ABS, which is the currently the world’s only eco-friendly ABS filament, and PLAyPHAb, a polyester enhanced PLA filament.ĮNVIRO is 100% pure ABS, made in the USA. Online giants such as Amazon and Best Buy already carry both products on their sites, and many other mainstream manufacturers have turned to 3D Printlife for their supply chain. Los Angeles-based 3D Printlife has carved out a niche for itself in the desktop 3D printing market by offering both functional and eco-friendly ABS and PLA solutionsĪpparently the solution proposed by 3D Printlife is perfectly suited for desktop 3D printing’s mass market ambitions, as several of the largest online big box stores are already offering 3D Printlife products, with Walmart (May) and Target (mid-June) soon joining a growing list of vendors. If you want to use ABS you have to consider that it is derived from hydrocarbons and thus not so good for the planet. Feel great about your world.There is a duality in desktop 3D printing: if you want to have an eco-friendly material you need to use PLA, which is fragile and brittle. manufactured, filler free, high-quality filament that leaves no carbon footprint in its wake.įeel great about your prints. The company’s slogan clearly defines their position in this industry, and their focus on U.S. Each spool is carefully wound to minimize cross overs and loopbacks that can lead to snags and snaps.ģD Printlife is truly at the forefront of the “green” 3D printing movement, and by donating a dollar of the proceeds from every spool of filament sold to plant a tree, they are continually giving back to the environment. Every inch of filament is measured with twin axis lasers that monitor the consistency of the diameter and roundness of the filaments. It is less stringy than PLA during print-head travel, and removing support structures is almost trivial and can be removed by hand.Īll of 3D Printlife’s filaments are made in the USA with the highest quality materials to the strictest standards available at their medical grade extrusion house. KVP and 3D Printlife partnered together to create the first complete line of eco-friendly ABS, PETG & Performance rPET 3D filaments under the product line. PLAyPHAb delivers higher UV and impact resistance than PLA, has excellent layer adhesion, and produces a glossy finish. PLAyPHAb is 100% biodegradable like PLA, but is comparable to ABS in terms of its pliability and ductile strength. The company also produces PLAyPHAb, a polyester enhanced PLA. The packaging has also been thoughtfully designed and Enviro ABS comes on a colorful spool made of 100% recycled cardboard with a tin end cap that is also recyclable. Unlike every other ABS on the market, 3D Printlife’s Enviro ABS has been specially formulated to be consumed by bacteria once it enters a landfill to energy facility or a commercial compost.

Enviro is the world’s only eco-friendly ABS filament.

0 kommentar(er)

0 kommentar(er)